Calculation Of Blank Length Cutting Sheet Metal

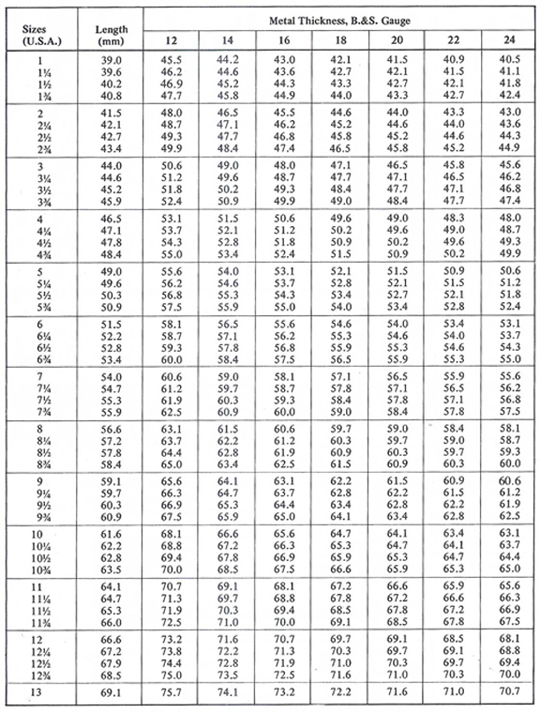

Ultimate tensile strength psi.

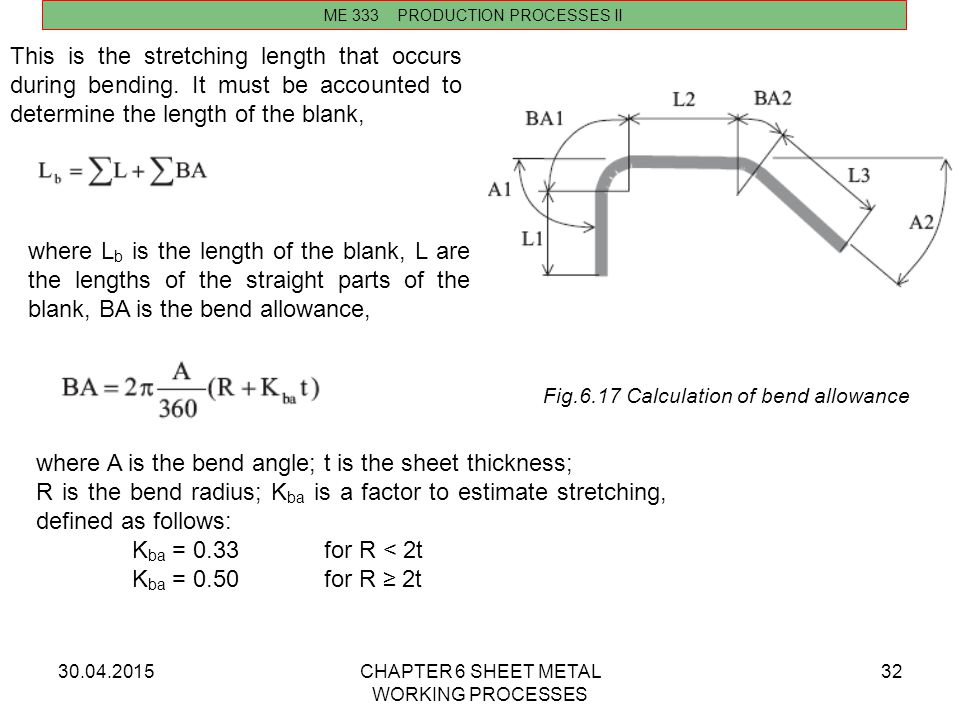

Calculation of blank length cutting sheet metal. This is used to calculate the back stop location when working off of a flat pattern. With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements. A 1 degree tolerance on all bend angles. Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

Consider a sheet with a 20 mm thickness and a length of 300 mm as shown in figure 1. Ultimate tensile strength psi. Cells on the right will output the desired values. Bends in sheet metal are manufactured using sheet metal brakes.

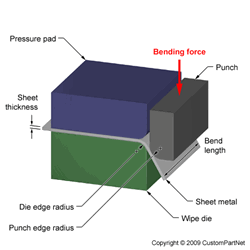

Keep default values in calculator as zero. Generate optimized cutting patterns based on the available stock sheets by nesting the required parts. R is inner bend radius. Wipe bending force calculator.

Here are the steps to be followed to calculate sheet metal flat length. In the settings box enter the length of the steel or wood that you will be cutting the required lengths from. Deep drawing force calculator. When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

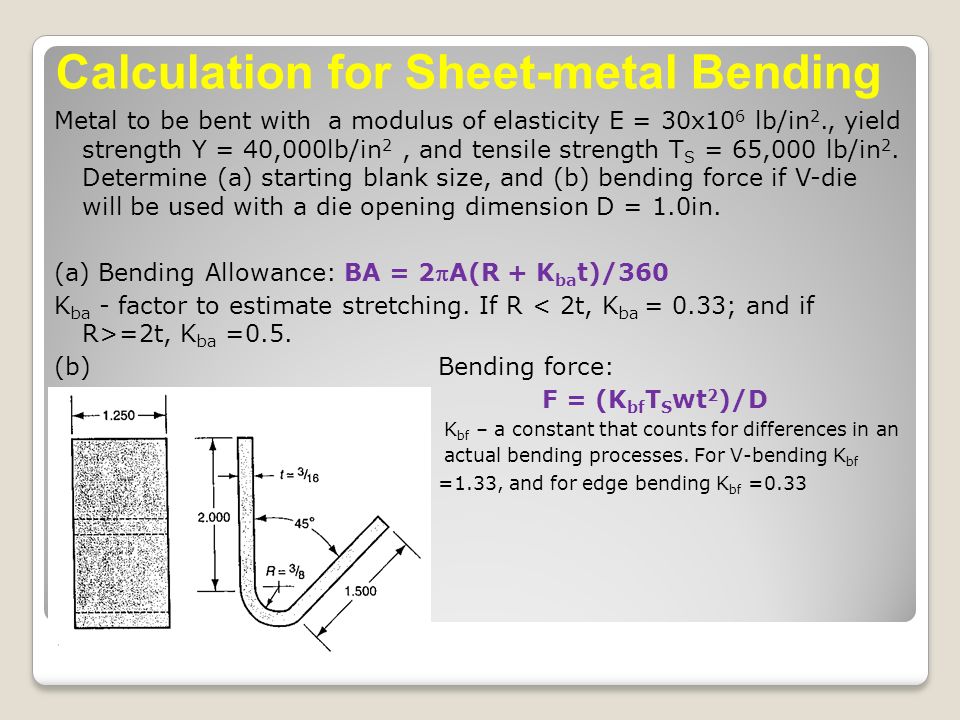

The formula for calculating sheet metal bending allowance is please refer to the above picture. Enter k factor values. Value of bend deduction and flat pattern are shown in result section. Air bend force chart a chart used to calculate the tonnage required for a bend based on thickness tooling and length.

Your measurements can be in inches feet cm centimetres mm millimetres or metres. You can calculate the punching tonnage been required with the help of the following punching force calculation formula blanking force formula. A lot of steel is not exactly the length that it is sold as. Bend angle represents the angle to which sheet metal has bend here it is 90 degree.

Punch edge radius in. Ba bend angle π 180 r k factor t eqn 1. Online panel cutting optimization software. Punching force calculation formula.

Use k factor calculator to calculate k factor values. 60 90 and 120 and we will calculate k factor bend allowance and bend deduction for them. Enter flange length internal radius and thickness values. If you punch round holes or square holes or some other forms of holes through a given thickness of metal you just want to know the force required to punch a hole in steel.

Die edge radius in. Where ba is bend allowance.