Cable Laid Slings And Grommets

To en 13414 1 and iso 7531.

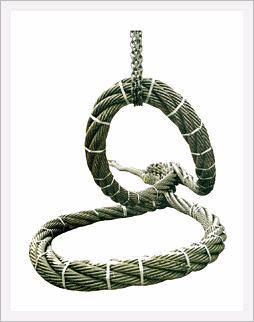

Cable laid slings and grommets. The minimum circumference of the sling is 96 times the grommet s body diameter. Either a hand splice or a mechanical splice then forms an endless sling body. Galvanized or ungalvanized steel wire rope grommet and cable laid sling with steel core ts 1770n mm2. Such operations often use cable laid slings and grommets of 100mm diameter and over as developed for use in the offshore oil industry.

A cable laid grommet is a sling in the form of a continuous endless loop similar to the cable laid rope a grommet consists of 6 strands twisted around a core wire unlike a cable laid rope a grommet is produced from one single length of steel wire rope. To align with current codes. Description and cable laid sling with steel core ts 1770n mm with our without thimbles or soft eye on both ends according to en 13414 3. 1 september 2016 to include additional construction methods.

The eye is the flemish type with a pressed on sleeve. Length tolerance for grommets ø 60 mm 1ø or 1. Flexibility is the outstanding characteristic of this type of sling. Facilities for measuring under load and proof loading.

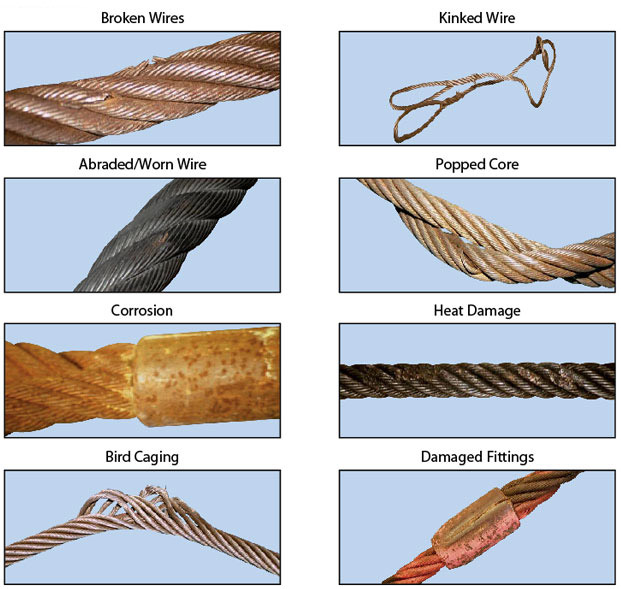

These are generally too large for existing test equipment to be used to test the rope sample to destruction. A grommet is a special type of sling which forms a continuous loop. Standard en 13414 3. Appendix 5 guidance on the assessment condition and discard of cable laid slings grommets and ferfs rev.

This note therefore gives advice on their construction rating testing certification. Single laid steel wire rope slings and cable laid grommets the steel wire rope sling is a very safe and versatile lifting product you may use it to lift to tension and to secure a load. Production of cable laid grommets. Grommets either have a wire rope body or a body made up of six strands which are laid helically around a strand core.

Thanks to a vast offer of end terminations available in the market the steel wire rope slings are for sure t he most commonly used device to lift a load. This extra flexibility is obtained by the use of special multi wire galvanized wire ropes. For the same benefits at a substantial cost savings you should buy tri flex slings. Each sling is made to specifictaions needed for rigging applications.